BWRX-300 Linda

Fermi Energia has selected GE Hitachi Nuclear Energy's BWRX-300 small modular reactor for deployment in Estonia by the early 2030s.

We gave it an Estonian but also an international name Linda.

Tenth generation of GE Hitachi fluidised bed reactors

The BWRX-300 is the latest, tenth generation of BWR designs developed by GE Hitachi Nuclear Energy. The technologies used in this reactor have proven reliability in previous generations of reactors and the newer solutions have been licensed by the US Nuclear Regulatory Commission (NRC). It is a small modular reactor with an electrical capacity of 300 megawatts, using naturally circulating water cooling (pumps are not required for reactor safety). Passive safety systems have been used to keep the reactor in a safe condition in all circumstances without human intervention.

The construction of the first builds the reactor Ontario Power Generation in Canada, and will enter commercial operation between 2027 and 2028.

The same type of reactor can be built in Estonia once all the necessary nuclear safety requirements are in place, a national regulator is in place to oversee the construction of the plant, and the first reactor under construction in Canada is completed.

Main features

Smaller – The BWRX-300 station fits on a land area of 170 x 280 meters. The grid connection switchyard, cooling tower, office, parking lot, warehouse and other necessary auxiliary buildings are within the boundaries of this area. The emergency planning zone is estimated to be about 8 hectares.

Cheaper - A small reactor nuclear power plant is called a. The small reactor reactor is smaller than a conventional nuclear plant and also requires less construction material, both in terms of total volume and electricity (MW) produced. Thus, the small reactor plant is more competitive than larger plants, as the smaller construction volume results in fewer construction delays (BWRX-300 can be built in 24-36 months). The simplicity of design and the proven performance of previous generations of BWRs also makes the BWRX-300 more cost-effective than other small reactors 60%.

Safer - passive safety systems reduce the risk of accidents, caused by the loss of cooling water. Reactor steam condensation and cooling systems based on nature laws, ensure the safety of the reactor without human intervention, even in the most severe case of an unlikely accident, for at least a week. After which it is sufficient to add cooling water using a conventional water pump or fire truck pump. It is also sufficient to use one of the four water reservoirs to cool the reactor.

in Estonia 2035 - Ontario Power Generation builds its first reactor of its kind Canada and it will enter commercial use in 2027-2028. During this construction, it is possible to monitor and evaluate the process and make preparations for construction in Estonia.

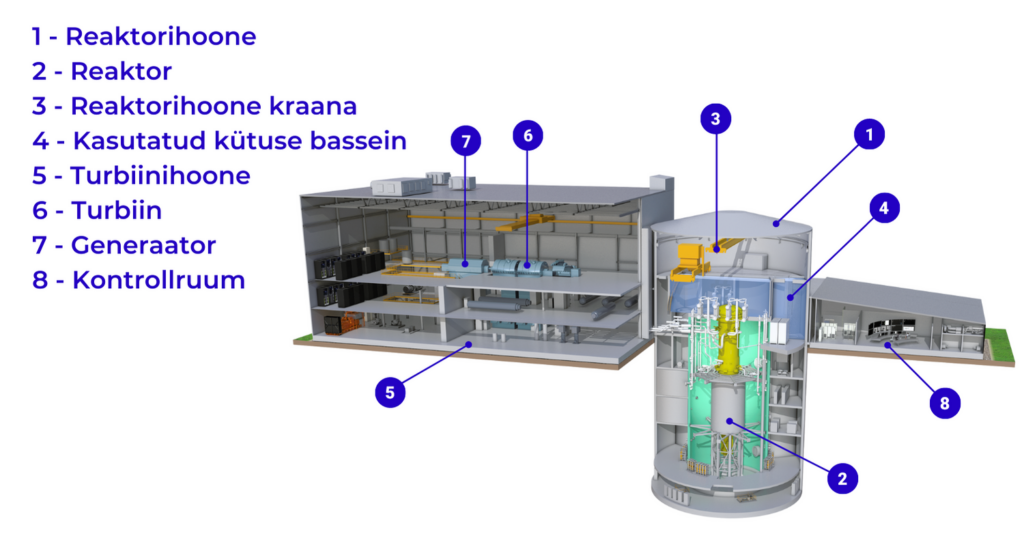

Main parts of the station

Main technical parameters

| Reactor type | BWR – boiling water reactor |

| Electric power output | 300 MWe |

| Thermal power output | 870 MWth |

| Coolant | H2O |

| Neutron moderator | H2O |

| Designed lifespan | 60 years (extendable) |

| Capacity factor | 95% |

| Ability to regulate power | 50-100% daily, 0.5% per minute |

| Fuel cycle | 12-24 months |

| Fuel type | UO2 |

| Fuel enrichment (average) | 3,4% |

| Emergency fuel | Not needed |

| Estimated probability of nuclear damage | Less than 10-7 per reactor year, i.e. less than 0.0001 % |

| Construction time (for 1 + n reactor) | 24-36 months |

| Construction cost (for 1 + n reactor), estimated | approx. €3.3 billion per 2 reactors |

| Cost of electricity generation, estimated | Below 100 €/MWh |

Source: aris.iaea.org

Can be done also in Estonia

Established efficient supply chain

The reactor and its main components (steam separator, steam dryer, control rods and their actuators) as well as the isolated condensation system are used in many reactors. Experienced manufacturers exist in the USA, Canada, Japan, Mexico and Europe (GE Power's turbine factories in France and generator factories in Poland). The supply chain does not have to be built from scratch.

Conventional components

The steam turbine and generator are off-the-shelf technologies produced by GE on a large scale. For example the TOPAIR generator has been manufactured, shipped and synchronized by GE in 3,570 units worldwide. Fermi Energia, in cooperation with Estonian mechanical engineering and manufacturing companies (Estanc, Estonian Heavy Indistries, Scanweld, BLRT, Maru, Aquaphor, Kunda Nordic Cement, etc.), is convinced that almost 30% of the components can be produced and delivered from Estonia.

Both in the USA and in Europe (Switzerland, Spain, Finland, Sweden, Germany) there are several energy companies with long-term safe and economical experience dealing with boiling water reactors. There is a group of BWR owners and a Japanese BWR Operator Training Center. Technology is familiar to national regulators and many technical support organizations. GE Hitachi has performed maintenance and replacement for dozens of reactors. The long-term operation of reactors (aging management) for 40-50 years is well known.