Are small modular reactors available?

- Small modular reactors have been built all over the world and are also used for commercial purposes.

- Fermi Energia has chosen the most likely option for Estonia, which has already undergone the authorisation procedure. BWRX-300 the design of a small reactor whose construction has started in Canada. Construction in Estonia would take into account Canadian experience at each stage.

- The BWRX-300 small-scale reactor is based on the well-known boiling water reactor technology used in America, Japan, Finland and Sweden, and therefore the know-how and supply chains are available in neighbouring countries.

What do we mean when we talk about a new generation of small modular reactors?

The reactors are relatively small in size and power.

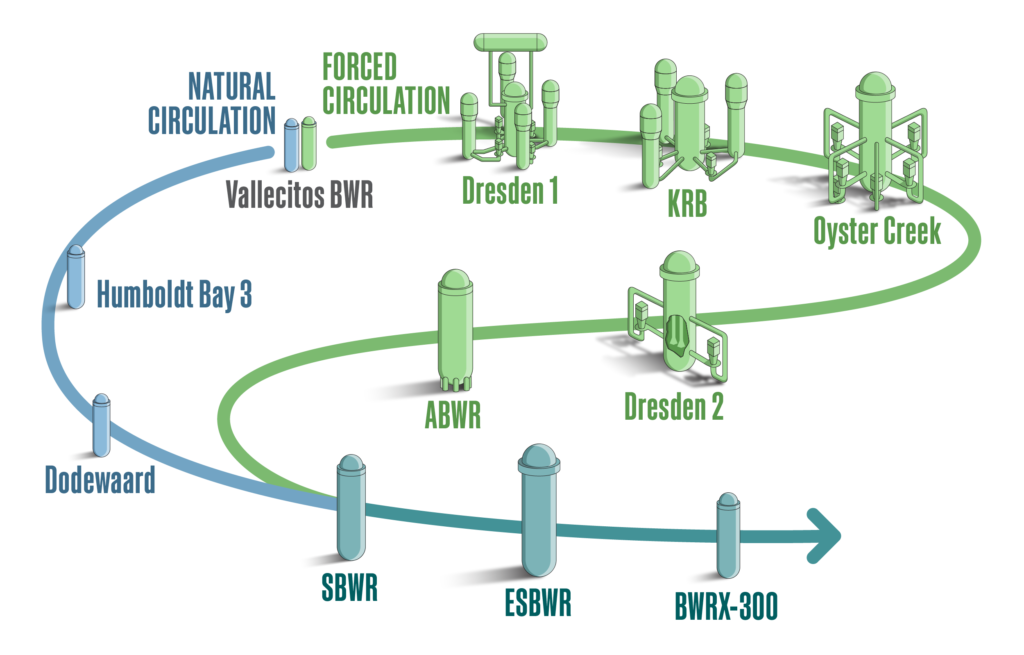

In the early days, the first nuclear reactors were small in both power and size.

As early as the 1960s, small nuclear reactors were used to generate electricity both in nuclear power plants and on ships, including submarines.

All of today's most modern US Virginia-class nuclear submarines are equipped with General Electric 210 MW small modular reactors.

According to statistics, there are more than 160 ships in the world powered by more than 200 small nuclear reactors.

The first privately financed nuclear power plant in the United States, the Dresden nuclear power plant, operated a 192 MW small boiling water reactor supplied by General Electric.

The first power unit was closed in 1978, but the other two units - also General Electric boiling water reactors - are still in operation and generate electricity for the grid.

The first nuclear power plant in the Netherlands, Dodewaard, was equipped with a 55 MW boiling water reactor supplied by General Electric.

General Electric is one of the oldest companies in the nuclear energy sector. They started the first nuclear research in 1939. General Electric licensed its first boiling water reactor in 1957. In total, General Electric has built 67 reactors in 10 countries around the world.

Nuclear plants can be built in modules

Modular assembly is a common practice in today's nuclear industry.

Modular construction technology is already used today in the construction of nuclear power plants. Large structural modules are produced in factories and then assembled on site.

The video shows a factory-prepared module being installed at the Sanmen nuclear power plant. The CA20 cubic module contains equipment for spent fuel storage. The module is 21 metres long, 14 metres wide and 21 metres high. The total lifting weight exceeded 1,000 tonnes, carried out with a 2,600-tonne crawler crane.

These are modern, not historical technologies.

Small modular reactors have been built all over the world and are also used for commercial purposes.

In China, the commercial-scale Generation 4 Shidaowan 200 MW small reactor power plant has been completed and is in operation.

The nuclear power plant uses high-temperature gas-cooled reactor technology.

For several years now, Russia has been operating a floating nuclear power plant, Akademik Lomonosov, with 32 MW small reactors.

Also in Russia, the RITM-200 175 MW small reactor is in commercial production. A total of 10 reactors of this type have been produced so far.

The West is actively developing its own small reactor technologies, and one mature example is General Electric Hitachi's BWRX-300 boiling reactor.

What are the criteria for choosing the right reactor technology and reactor design for Estonia?

GE Hitachi BWRX-300 is a state-of-the-art welding reactor

Fermi Energia has selected the General Electric Hitachi BWRX-300 BWR as its small reactor technology. This reactor technology is well known and used in America, Japan, Finland and Sweden.

The main selection criterion was the extensive experience in the development of both large and small reactors that GE Hitachi has. They have also already started the licensing and construction of the same reactor in Canada. This adds to the certainty that the technology can be built within a realistic budget and timeframe, will perform well when completed, the plant parameters will be known to both operators and the regulator, and because of the pervasiveness of the technology, monitoring and verification skills can be learned from neighbouring countries.

Fermi's reference technology for a nuclear power plant under construction in Canada

To date, four customers have committed to build the BWRX-300 boiling water reactor:

- Ontario Power GenerationFour reactors planned and the pre-licensing* process is complete. Pre-construction work is underway and the pressure vessel (the most important part of the power reactors) has already been ordered and its production takes place in At the plant of BWX Technologies, a Canadian manufacturer of nuclear reactor components, 100 km east of Toronto.

- Province of Saskatchewan Energy Company

Four reactors are planned.

- US National Energy Administration TVA

Plans to build two reactors.

- Poland OSGE

The plan is to build 79 reactors, which means about 10 reactors per year. The decision in principle has been taken to build 24 reactors at six stations.

The BWRX-300 is based on well-known technology

BWRX-300 on Generation III+ small light boiling water reactor.

The reactor has a capacity of 300 MW, making it a smaller and safer version of GE Hitachi's boiling water reactors. The larger version, the GE Hitachi III+ generation ABWR reactors, is currently in operation in Japan.

BWRX-300 The technologies used have proven reliability in previous generations of reactors and the newer solutions have been licensed by the US Nuclear Safety Administration.

Fuel comes from Western countries and is standard

The BWRX-300 uses standard fuel for boiling water reactors (fuel composition model GNF2) produced in Western countries - no dependence on nuclear fuel supplies from Russia or other unfriendly countries.

BWRX-300 reactor innovation

Passive cooling

The BWRX-300 mainly uses unpowered systems that do not require human intervention (so-called passive systems), both in normal and emergency mode.

More information on the BWRX-300 reactor can be found at. from here.

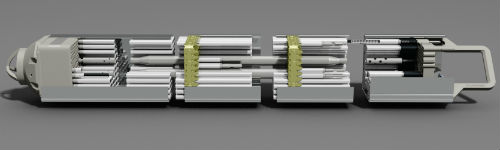

Steel Bricks terasmodules

The BWRX-300 reactor plant will be built using Steel Bricks steel modules. These modules are the main construction technology, which allows for a faster, cheaper and less labour-intensive construction process compared to conventional reinforced concrete.

A full-size example of this module can be found in front of the Kunda Cement Museum, home to Estonia's first nuclear power display. The Atomic Room.