Choice of technologies

The SMRs are, by interntional definition, nuclear reactors with up to 300MW electrical output capacity.

"Small" means that the power (and also the dimensions) are significantly smaller compared to the reactors (1000+ MW) mostly in use today. Reactors from different manufacturers vary from a few megawatts up to 300 MW, some even slightly larger.

The "M" stands for modular. It means thatthe reactor is transported to site as modules or as a single unit. This simplifies and shortens the building process, making the plant cheaper to build.

Large NPP in Finland

SMR power plant

- Standardized components

- Factory-built reactors

- Shorter construction time

- Less materials used

- Less nuclear fuel used

Small modular reactors are the technology of the near future for nuclear power. Small modular power plants are nuclear in principle, but very different in construction, safety and economics from the large, high-performance nuclear plants of the 20th century. They are dozens of times smaller - they take up less space, but still produce a lot of CO2-free clean electricity, whatever the weather and whatever the time of year.

Therea are over 50 SMR designs in development around the World. Fermi Energia is assessing those technologies in order to choose the best option to be built in Estonia - after it has been built and tested in countries already using nuclear power - UK, US, or Canada.

Since 2019, Fermi Energia has been analysing a number of potential reactor technologies, which have been screened out by feasibility study (pdf) in Estonian language. An important selection criterion is that the reactor model in question must first have been built and proven in practice in the US, Canada or the UK, where there are competent inspection authorities.

Technologies available

300 MW electrical capacity a modular reactor, the design of which is based on the same company's 1520 MWe ESBWR boiling water reactor that passed the NRC licensing process in the US in 2014.

The reactor does not have circulation pumps, but instead uses a convection cooling system to cool the residual heat of the nuclear fuel. This system is very safe and in the event of an emergency it will operate for 7 days without human intervention and without external power, after which it will be necessary to add water to the cooling pool, using station pumps or even a fire engine pump. The station will benefit from proven technologies and design solutions, ensuring the use of known delivery and training systems. In addition, the construction size of the plant is half per 1 MW and the safety structure requires ten times less concrete than an ESBWR.

The development of the reactor started in the early 2000s, in 2017 the licensing process began at the US nuclear regulator NRC..

The development of the reactor started in the early 2000s, in 2017 the licensing process began at the US nuclear regulator NRC..

The first plant based on this technology will consist of twelve modules with a thermal capacity of 200 MW and a gross electrical capacity of 60 MW, i.e. a total electrical capacity of 720 MW gross / 685 MW net (a plant with 6 modules would be suitable for Estonian conditions). The reactors will use classical pressurised water reactor technology, but instead of pumps, cooling water will circulate naturally through the reactor core and steam generators.

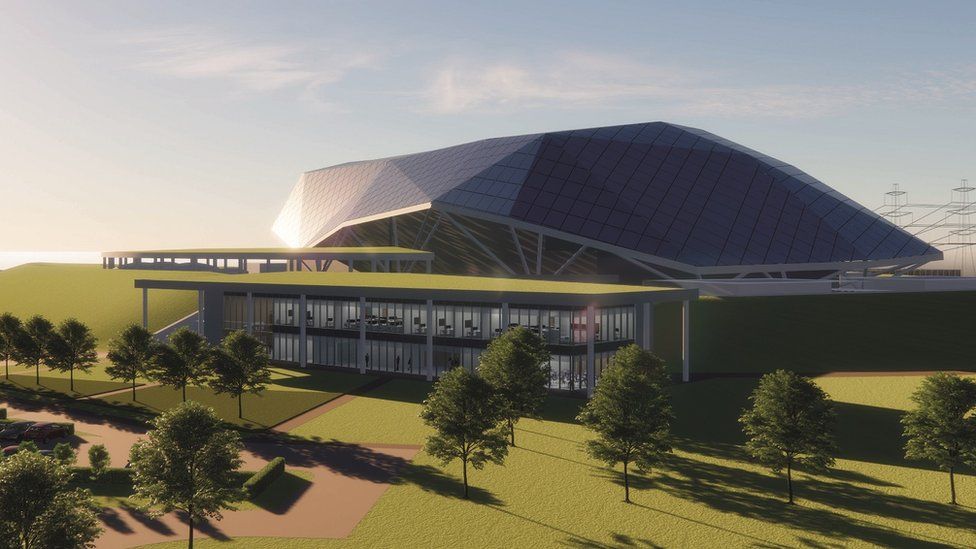

In addition to manufacturing cars and jet engines for airplanes, Rolls-Royce is also known as a manufacturer of steam turbines and reactors. Rolls-Royce has more than 60 years of experience with submarine reactors of British Navy. The pressurized water reactor they are developing is slightly more powerful - with an electrical capacity of 470 MW.

In addition to manufacturing cars and jet engines for airplanes, Rolls-Royce is also known as a manufacturer of steam turbines and reactors. Rolls-Royce has more than 60 years of experience with submarine reactors of British Navy. The pressurized water reactor they are developing is slightly more powerful - with an electrical capacity of 470 MW.

UK SMR uses passive safety systems, the design life is 60 years, and the developer estimates that it will take 4 years to build the station.

Approximately 90% of the production and assembly operations are carried out in factory conditions, which ensures higher quality and avoids delays compared to the construction of the reactor at the construction site of the nuclear power plant.

See more Rolls-Royce SMR website from the website.

Gallery

Winner of the Technology Choice

Fermi Energia selected the GE Hitachi small modular reactor as the most suitable one for development in Estonia among three bidders in early 2023. BWRX-300, the first construction of which began at the Darlington nuclear power plant outside Toronto, Canada. Building on the Canadian experience, we can also plan the construction of a plant in Estonia.