Research

Surveys and their main results by sector

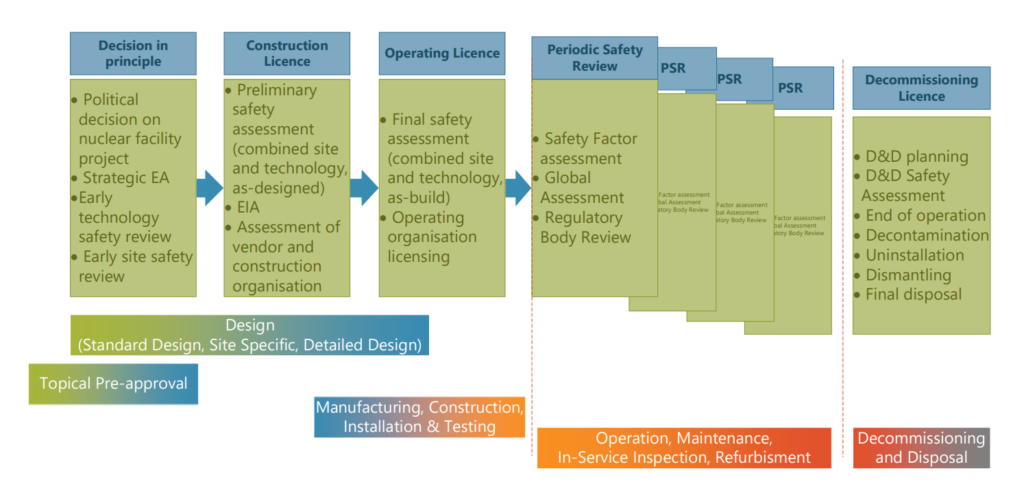

The deployment of nuclear energy will not happen overnight. It will be preceded by a long period of preparation, during which it will be necessary to determine whether nuclear power is the right choice for Estonia, whether a suitable location for the plant can be found, and whether construction and subsequent operation are feasible and affordable. The full range of associated impacts - on the environment, the economy, external relations, local development, the research sector, etc. - must also be analysed.

The Fermi Energy study plan is based on IAEA "Convergence of Milestones". Consideration of the use of nuclear energy and the subsequent development of the necessary infrastructure will go through a number of phases before the plant is completed and operational, which, based on experience to date, will take around 10-15 years. According to today's best knowledge, the introduction of small reactors in Estonia is. feasible between 2031 and 2035.

The results of all completed studies are publicly available and accessible. publications footer.

It is also important to bear in mind that the studies are based on the information available at the time, so further studies, analyses and decisions will need to take into account any refinements and changes that have occurred in the meantime (e.g. inflation, new technical solutions, changes in regulations or the environment).

Choice of location

Preliminary study on the location of a small modular reactor - Tractebel and Steiger OÜ - summary in Estonian (PDF, pp 4-7)

N.B. The choice of location for the plant has to be made during the national specific planning process, this choice cannot be made by the developer Fermi Energia.

It only makes sense to plan a nuclear power plant where it can operate safely and with the least possible impact on its surroundings. It is also wise to exclude unsuitable sites when selecting possible locations. When selecting a possible site for a nuclear power plant, all factors must be considered as a whole, so that both the safety of the plant and its minimal impact on the surrounding environment, including people and the natural environment, ensure. It is not rational to build a nuclear power plant in areas prone to flooding, on the banks of the coast, on the edge of large towns, in a nature reserve, far from major transmission lines or cooling water, or where the geology is not favourable. Understanding and support from the local community is also an important factor, without which it is impossible to do business in a democratic country.

The preliminary study has shown that there are several suitable areas in Estonia where a number of suitable sites for a small modular reactor can be found. The best locations are on the coast of North Estonia, east of Tallinn.

Cost-effectiveness

Economic viability

The economic impact of the VMR plant on Estonia in 2019 by the Centre for Applied Social Science Research at the University of Tartu. The assumptions for the study were based on baseline data provided by Fermi Energia, submitted by reactor manufacturers and other partners and validated by the engineering company Tractebel:

- Reactor manufacturer's estimate of the overnight capital cost for the design, procurement and construction of a nuclear power plant - - 1 billion USD

- Fermi Energy assessment of the investment structure

- Reactor market viability and Estonia's readiness to go nuclear by the early 2030s

- Estimation of the cost of network construction by Elering

- VTT and Riser Ehitus OÜ labour needs assessments

- Fermi Energy forecast for electricity generation costs

The main findings of the pre-feasibility study were:

- More than €300 million worth of goods and services sourced in Estonia (construction activities, concrete and possibly partly steel components production)

- €100 million in direct tax revenue until the reactor is completed (mainly labour taxes)

- Avoiding €130-150 million of electricity imports per year (for an electricity exchange price of €53/MWh - €60/MWh and a production price of €40/MWh).

- Economic recovery in the area around the power plant and nearby settlements

- Profit for owners of €32-50 million in the first years (expected to repay the loan). At the same production price and electricity exchange price, the profit after full repayment of the loan would be €60-78 million per year.

- Possible attraction of additional investment and high value-added industry in the vicinity of the plant (free electricity for direct line consumers of grid maintenance).

- The PÕXIT strategy, however, with similar GHG emissions to wind power, allows for stable security of supply.

Socio-economic impacts

A more detailed analysis of the socio-economic impacts of the small modular reactor plant will be completed by 2022. The main impacts are described in the ex ante feasibility study.

Environmental impacts

A more detailed assessment of the environmental impacts will be carried out as part of the Strategic Environmental Assessment (SEA) and will be based on the site conditions. The meso-zonal impacts are derived from world practice in the construction and operation of nuclear power plants.

Every human activity has an impact on its surroundings, and this is also true for nuclear power plants. The main continuous environmental impact of nuclear power plants could be considered to be the cooling of steam turbine steam. In inland locations in central Europe, this is done with cooling towers or gradients up to 200m high, but with seawater in the seas. This cooling function is the same for all condensing power plants. At Narva power plants, turbine steam is cooled by water from the Narva River.

The nuclear power plant itself is no more radioactive than the natural radiation phonon. All radiation from the fuel is shielded by cooling water, reactor pressure vessel and concrete. Extensive measurements have been made around Finnish nuclear power plants and no significant increase in radiation levels has been detected. Compared to emissions from shale and wood chip combustion, the environmental impact of both large and small nuclear power plants is much smaller.

Significant environmental impacts are the correct management of spent fuel..

Technology selection

Considering that Estonia has no previous experience in operating nuclear facilities and that there is a need to establish basic competence and ensure training of specialists, the IAEA experts recommended the following principles for the choice of technology:

Exclude the first of its kind (First of a Kind, FOAK) - Estonia should not allow a reactor developer to build the country's first reactor plant of its kind, as they can be difficult to operate even for an experienced nuclear state and there is a lot of uncertainty in the process. When selecting a suitable reactor type, it was recommended to look at reactors already in commercial operation somewhere, where there is sufficient information and solutions on the construction process, cost, fuel and spare parts supply chain.

Do not choose a technology with which you have very little experienceIf a very exclusive reactor type had been chosen, which has not been sufficiently tested in the history of nuclear power generation, the elimination of technical failures could have proved difficult and time-consuming because of the scarcity of technological experts. It could also have been difficult to obtain the necessary spare parts, regular maintenance, fuel exchange, training of regulator and operator staff.

Select the reactor type for which fuel is produced by more than one manufacturer. - for a reactor using a very unique fuel, it would be difficult to find alternative manufacturers and the operator would most likely be dependent on a single supplier, which could jeopardise security of supply. The experience of the new nuclear countries shows that securing fuel supply is essential for the deployment of the technology. Typically, the construction contract only includes an initial shipment of fuel and a few additional shipments. Long-term fuel supply is ensured by one or more additional contracts.

Choose technologies for which technical know-how is available in neighbouring countries. - if the operator and the staff of the nuclear safety authority can be trained in neighbouring countries and have experience in the use of a particular reactor technology, this will allow significant cost savings and ensure faster technical assistance in the event of a potential failure. Once the decision in favour of a particular technology has been taken in neighbouring countries, it will be easier to deploy the same reactor type in one's own country, as it will be possible to build on the experience and practice of another country, organise joint procurement, training, etc. This will make it easier to ensure that the same reactor type is used in the same country.

FOAK completion dates are closer for water-cooled reactors based on III+ technology, as most of the infrastructure for the production of these components is already in place today. The first reactors will be ready in 2028. This is why Fermi Energia chose GE Hitachi, an experienced reactor manufacturer, for the small modular reactor. BWRX-300, the principles of which are well known in Finland and Sweden and the safety of which is proven. It also makes the process of issuing permits for them simpler and quicker, as regulators can rely to a large extent on existing standards and guidance material for this technology.

Licensing

Since no reactor technology is being developed or licensed in Estonia, and there are no plans to license it, the introduction of nuclear power in Estonia requires first licensing the reactor in the country where it is first planned to be built. In such a case, Estonia should have the capacity to assess and take over the licence issued by that country - similar to cars produced in the US or Japan, which have been assessed by experts here for safety compliance with EU and Estonian road safety requirements, and have been granted a European type-approval so that the car can be registered and used on the road.

Licensing primary survey was made by the Finnish energy company Fortum.

Licensing of the technology chosen for use in Estonia principles and Tallinn Declaration has been proposed as a starting point for the licensing process in Estonia.

Fuel cycle and waste management

The planning of any nuclear power plant includes the development of a waste management plan. Waste management is part of a plant's fuel cycle.

Spent nuclear fuel is characterised by high levels of radioactivity. Radioactivity is invisible but not unknown - over the centuries, scientists have studied it in depth and developed standards and working methods for handling radioactive materials in a way that does not pose a risk to the operator or the surrounding environment.

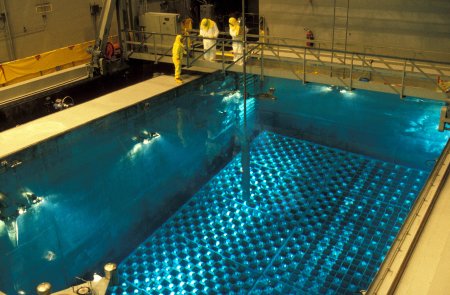

The logistics of waste management at a nuclear power plant can be summarised in a simplified way in three parts - spent fuel storage at the plant in a spent fuel pool, intermediate storage, and final storage. This may be supplemented, for example, by the reprocessing of the waste into new nuclear fuel or for some other purpose, such as waste reduction.

Spent fuel assemblies are lifted out of the reactor and placed in a water-filled pool next to the reactor. The reactor is located in a water-filled space at all times, and there is enough water above the reactor to allow the fuel rod to be lifted out and placed in the cooling pool without any danger from the radiation emitted.

Radioactivity levels in spent fuel are relatively high when it is removed from the reactor, but are falling rapidly. During this time, it is safest and most practical to allow the spent fuel pool to "cool down" before further disposal.

After initial storage at the plant, the radioactivity level of spent fuel has decreased sufficiently to allow it to be stored in a special interim storage facility. The radioactive materials are sealed in a special shielded container and transferred to an interim storage facility where the radiation levels will further decrease over the years.

At present, most of the world's spent nuclear fuel is stored in interim storage - a very valuable and reprocessable material that can be reused in certain types of nuclear reactors. France recycles about a tenth of its nuclear fuel. as MOX fuel.

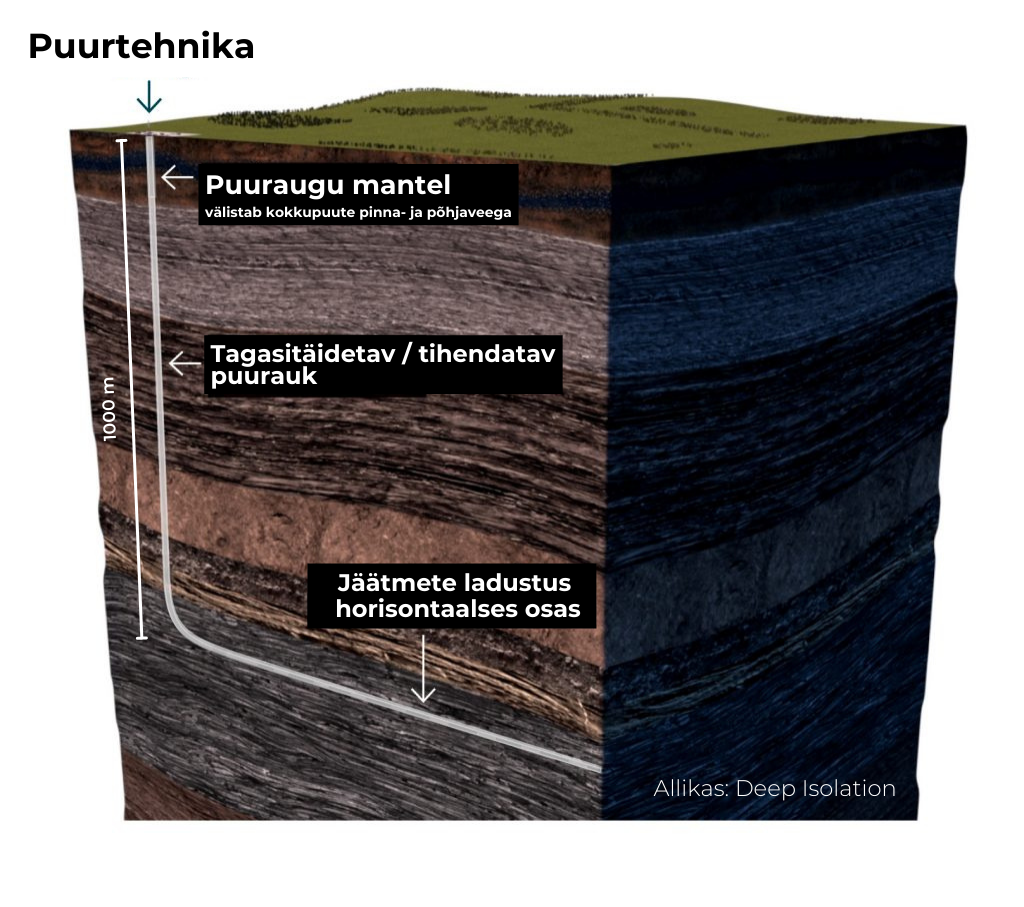

The final stage in the storage of nuclear waste is final disposal. Although significantly lower than the initial levels, the radioactivity of spent fuel will remain harmful to living organisms for a very long time. Exposure of the waste to the biosphere must therefore be excluded for a very long time - at least hundreds or thousands of years, depending on the composition of the materials and the half-lives of the substances.

Since in some parts of the Earth's crust the bedrock has remained unchanged for billions of years and will continue to do so for at least as long, the best place for nuclear waste is deep underground. In Finland, the crystalline bedrock (granite in common parlance) is exposed at the surface, while in Estonia it is under sedimentary rocks at a depth of a few hundred metres.

The construction of the final recharge in the crystalline matrix is underway, both in terms of. In Finland and In Sweden - there will be repositories at a depth of about 450 metres. Finland and Sweden have large nuclear plants and more spent fuel, so a larger repository is suitable.

A smaller station is suitable for Estonia. As a smaller station also produces a smaller amount of spent fuel, it is possible to a smaller-scale waste management solution - deep pits - would be better suited to Estonia. Deep drilling is widely used in the oil industry, for example, so the technology and skills needed to use it are widely available worldwide. The US company Deep Isolation has also developed a suitable solution for the disposal of nuclear waste, a more detailed presentation of which can be found at from this video.

The conditions under which and where to build deep well technology-based final disposal in Estonia are. researched by Deep Isolation in collaboration with engineering firm Steiger.

The suitability of the Estonian bedrock for the geological final disposal of used nuclear fuel

Made by Taltech, 2023

Developing skills and the workforce

IAEA Milestones Approach contains a roadmap for the development of the infrastructure, workforce, legislation, etc. needed for the deployment of nuclear energy, both for the developer (Fermi Energia) and the Estonian state. Overview of competences required has been made by Fortum, Finland's national energy company.

The development of competences is a long and time-consuming process to which we are already contributing with scholarships for master's studies at foreign universities well as domestic summer schools and the free courses for modern nuclear energy at TalTech.

In Estonia, the training of nuclear energy experts is a task for Fermi Energia and, in the future, also partly for the state, as education and research will benefit the whole of Estonia through budget revenues, reduced electricity import needs, energy security and climate targets.

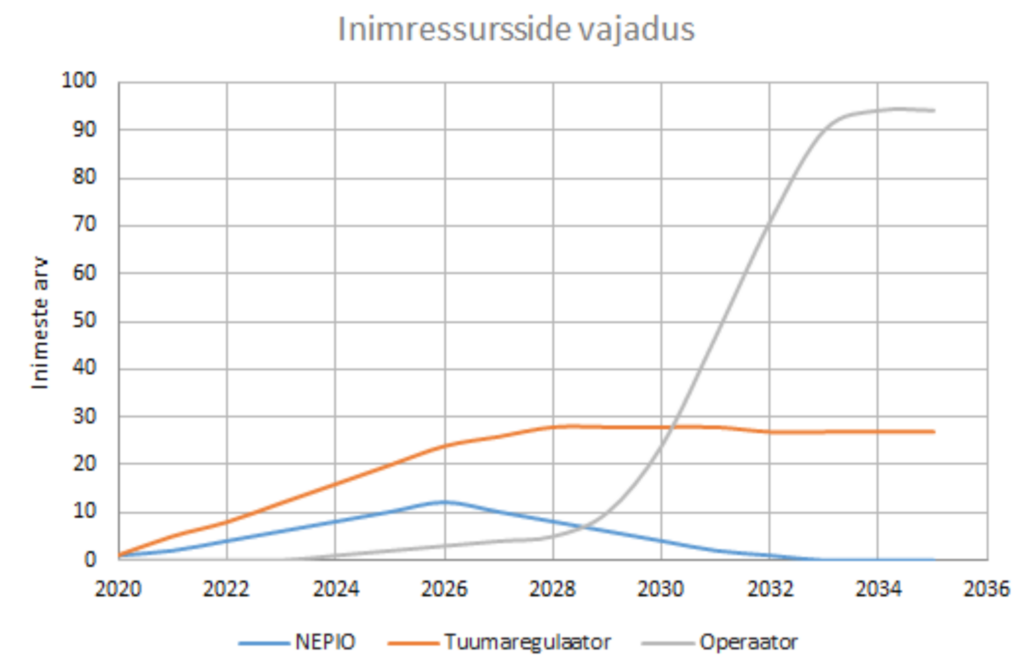

Experts are needed by both the operator and the national supervisor

Above all, competent people are needed to join the ranks of the future operator, i.e. the company developing the project (estimated at. 70-150 people). The second largest and most important organisation from a national perspective is the nuclear regulator, the National Supervisory Authority (estimated at 30-50 people). For example, the Slovenian nuclear regulator employs just over 40 people to oversee the 700MWe Krško nuclear power plant. The amount of resources needed in universities and research institutes depends on the strategy chosen, whether and how much nuclear research capacity we want to have in Estonia.

In addition to the above, a certain level of competence and relevant knowledge is also needed in ministries and other government departments and agencies where staff already exist (e.g. ambulance, fire brigade, police). In addition, there are also potential Estonian construction companies and suppliers of components.

Developing a nuclear energy policy means in practice (presumably - the Government of the Republic will choose the appropriate way) hiring additional staff and training in the Energy Department of the Ministry of Economic Affairs and Communications and the Climate and Radiation Department of the Ministry of Environment. The competence to carry out planning already exists in the Ministry of Finance and other agencies. Fermi Energia, as an interested party, is obliged and willing to cover the costs related to the planning activities and the strategic environmental assessment.

After the decision in principle in favour of the nuclear option, the national regulator and/or the relevant areas of the Environment Agency and the Nuclear Safety Authority will also need to be staffed.

The main organisation assisting and advising countries preparing to go nuclear is the International Atomic Energy Agency, which operates independently within the UN system. IAEA, which assists Member States with various guides, training programmes and expert missions. World Association of Nuclear Operators (WANO) organises a range of training and peer-review programmes. The Western European Nuclear Regulators Association (WENRA) helps to ensure that nuclear safety is maintained at a consistently high level in Member States around the world. There are many other organisations and training and assistance programmes. In addition, transnational cooperation programmes, for example between neighbouring countries, also play an important role. Once a project is so far advanced that a specific reactor technology is selected, the supplier of that technology will help to train the engineers and the more detailed technical knowledge of the specifics and nuances of the particular design, also providing training for future operators to ensure that the necessary competence is in place when it is needed.

Safety indicators

Every power plant, including nuclear power plants, is an industrial environment that requires a proper safety culture, i.e. appropriate safety requirements and adherence to them. Keeping order and cleanliness in a nuclear power plant is elementary.

Because of the very high energy density of nuclear fuel compared to traditional shale fuels, nuclear fuel naturally requires special safety precautions when handling, processing, transporting and using the materials in a nuclear reactor.

The greatest potential risk of damage at a nuclear power plant is meltdown of the reactor core. Such an event is potentially dangerous for both people and the environment, so it goes without saying that the likelihood of a core meltdown has been made virtually impossible in new reactor designs to ensure nuclear safety. This is done through additional cooling, multiple emergency systems, modification of the reactor design and reduced fuel load. However, the likelihood of highly unlikely events must also be calculated - while in older plants this was no more than once in 10 000 reactor years, in new reactors the meltdown of the core is already estimated to be as high as 1 in 10 000 reactor years. no more likely than once in a million or even outright billion during the reactor year. For certain technologies, however, nuclear fusion is already physically impossible.

To set up in Estonia, we are considering only passive safety systems technologies - the safety of the reactor is ensured by the laws of physics (free convection, gravity, ...) and no human intervention or external electricity is required. The cooling of the reactor does not depend, for example, on pumps that need electricity. For an overview of the safety parameters of small reactors see from here.

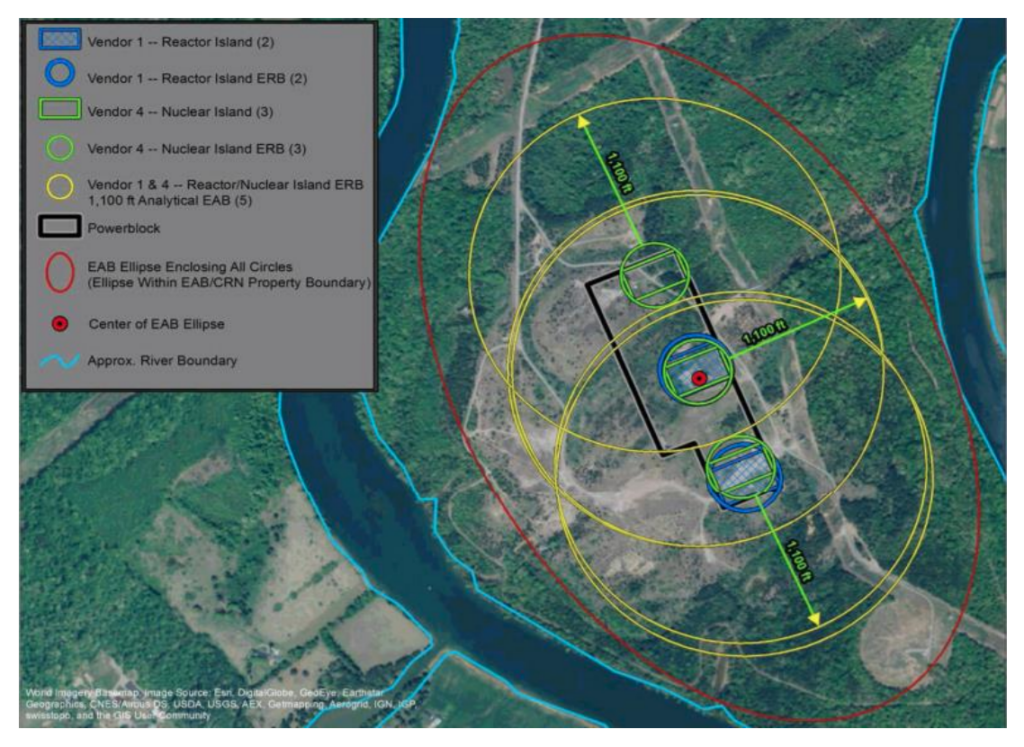

Emergency planning area

Each power plant has an emergency planning area. While the radius of these areas can be up to a few tens of kilometres for large nuclear plants, smaller nuclear fuel pools can mean that the emergency planning areas for small modular reactors can even fit within the station's territory.. Corresponding Preliminary research has been made by KBFI.

Station security

Studies carried out:

Physical protection strategy study

Deadline: summer 2023

Produced by Vattenfall AB

By-production

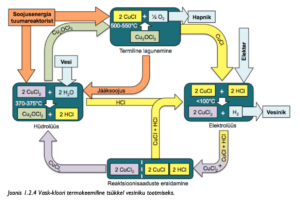

In addition to producing CO2-free electricity, the nuclear plant can also produce. heatjust (both for heating settlements and for process heat and process steam for businesses) than, for example hydrogen, ammonia than other synthetic fuels..

Hydrogen is a key raw material in the production of fuels, fertilisers, plastics and other commodity chemicals. Conventional hydrogen production methods, such as methane steam reforming and coal gasification, are reliable and cheap, but very CO2 intensive (over 12 kg CO2 equivalent for every kg H2 produced). The more the CO2 emissions of industrial plants come under scrutiny, and the higher the price of CO2 quotas, the more pressing the issue becomes for industry: "Where to get green (low CO2 footprint) hydrogen?". Given (1) the EU's carbon neutrality target for 2050, (2) the linear reduction of free emission allowances to zero and the consequent expected increase in emission allowance prices, the production of hydrogen in the EU through steam reforming will become increasingly expensive, while hydrogen with a low CO2 footprint will become increasingly attractive.

Technical-economic analysis found that using alkaline electrolysis, the most widely used electrolysis technology today and the cheapest in terms of capital costs, to produce hydrogen, 100 MW of electrical power can produce about 1 700 kg of hydrogen per hour.

The same analysis also looked at the production of ammonia and aviation fuels using nuclear energy.

Public opinion

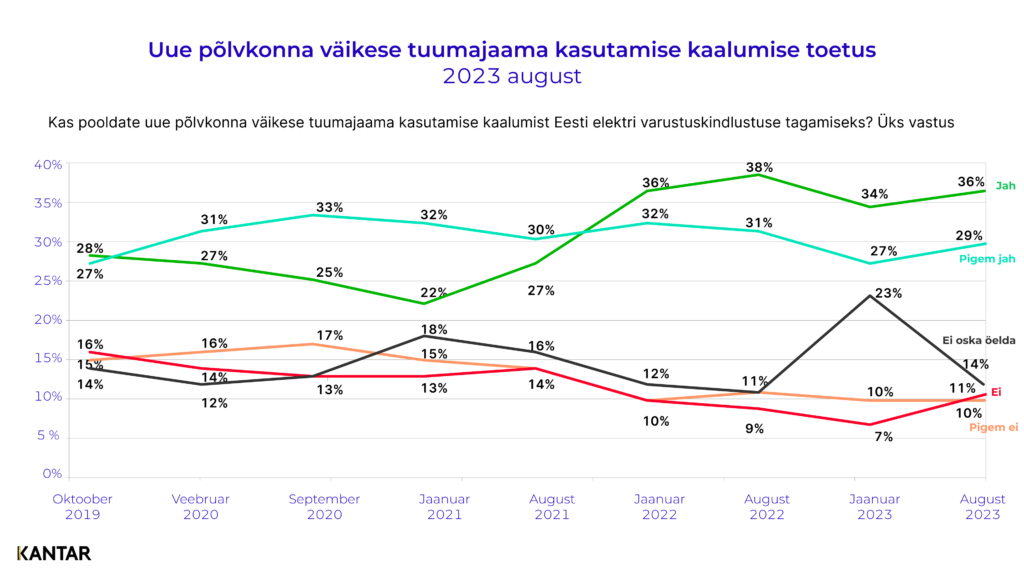

Fermi Energia commissions surveys on attitudes towards nuclear energy deployment on a regular basis from 2019. In addition, public opinion polls on nuclear energy are also carried out by the Chancellery and the Ministry of Climate Change.

The latest opinion survey commissioned by Fermi Energia and conducted by Kantar Emor in mid-August 2023 showed that a total of 36% (29%) are in favour or rather in favour (36%) of considering the use of a new generation of small nuclear power plants to ensure Estonia's security of electricity supply. 65% Population. Read more from here.

According to a survey carried out by the Chancellery in March 2023, support for the 75% of the people of Estonia in favour of a nuclear power plant in Estonia. Read more from here.